In the quest for sustainable energy solutions, the oil and gas industry is increasingly turning to innovative technologies to minimize environmental impact while maximizing efficiency. One such innovation is the dissolvable frac plug, a revolutionary tool designed to enhance well completion operations while reducing waste and preserving environmental integrity. Developed by industry leaders like Vertechs, dissolvable frac plugs offer a sustainable solution for isolating wellbore zones during hydraulic fracturing operations.

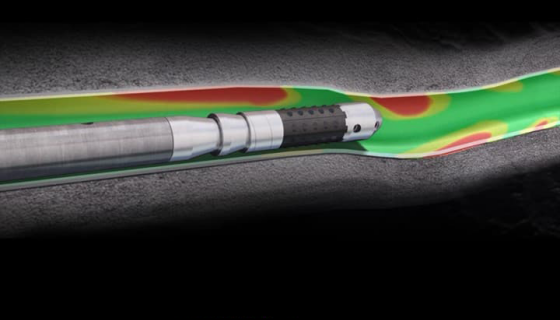

Dissolvable frac plugs are advanced downhole tools engineered to temporarily isolate specific zones within the wellbore during hydraulic fracturing operations. Unlike conventional frac plugs, which require mechanical retrieval after fracturing is complete, dissolvable frac plugs are made from materials that naturally dissolve or degrade in the downhole environment over time. This innovative design eliminates the need for costly plug retrieval operations, streamlining the well completion process and minimizing environmental impact.

One of the primary benefits of dissolvable frac plugs is their ability to reduce waste generation during well completion operations. Traditional plug-and-perf methods involve milling or retrieval operations, which can generate significant amounts of debris that must be removed and disposed of properly. Dissolvable frac plugs eliminate the need for plug retrieval, as they dissolve or degrade in the downhole environment, leaving behind no debris to remove or dispose of. This reduction in waste generation contributes to a cleaner, more sustainable operating environment.

Dissolvable frac plugs play a vital role in preserving environmental integrity during hydraulic fracturing operations. By dissolving or degrading in the downhole environment, these plugs minimize the risk of formation damage and fluid migration, protecting surrounding ecosystems and groundwater resources. Additionally, the elimination of plug retrieval operations reduces the disturbance of surface ecosystems, further minimizing environmental impact and ensuring compliance with regulatory standards.

Dissolvable frac plugs streamline the well completion process by simplifying deployment and eliminating the need for plug retrieval operations. Unlike traditional plug-and-perf methods that require multiple trips in and out of the wellbore, dissolvable frac plugs can be installed in a single run. This streamlined deployment process reduces rig time, operational costs, and environmental footprint, enabling operators to achieve faster turnaround times and accelerate time to production.

In addition to environmental benefits, dissolvable frac plugs offer significant cost savings compared to traditional plug-and-perf methods. By eliminating the need for plug retrieval operations, dissolvable frac plugs reduce rig time, equipment costs, and personnel expenses associated with well completion operations. Additionally, the simplified deployment process and reduced risk of formation damage contribute to overall cost efficiency, improving project economics and maximizing returns on investment for operators.

Partner with Vertechs Group for cutting-edge energy solutions. Visit us at Unit 2, Building 6, No.1166 Tianlong Avenue in Chengdu, or browse https://www.vertechs.com/ to learn more. Contact us at +86 28 8325 7686 or through email at admin@vertechs.com and marketing@vertechs.com for expert guidance in your energy endeavors.

Read Our One More Blog(1): Precision in Motion: The Advanced Capabilities of Vertechs' Fluid Monitoring System

Read Our One More Blog(2): An In-Depth Guide to Managed Pressure Drilling (MPD): Definition and Technology