In the realm of oil and gas exploration, High-Pressure High-Temperature (HPHT) environments present formidable challenges. These conditions demand specialized equipment capable of withstanding extreme pressures and temperatures encountered during fracturing operations. Among the critical components essential for success in such environments are HPHT frac plugs. Vertechs, a leading provider of oilfield solutions, has been instrumental in developing innovative HPHT frac plug technology, engineering resilience to overcome the challenges of HPHT fracturing operations.

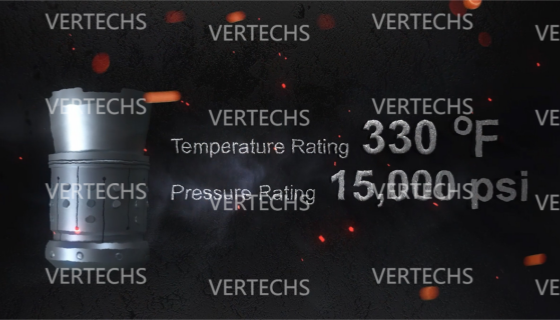

HPHT frac plugs are indispensable tools used to isolate sections of the wellbore during hydraulic fracturing operations in HPHT environments. These plugs are subjected to pressures exceeding 15,000 psi and temperatures surpassing 350°F, requiring robust design and construction. HPHT frac plugs play a crucial role in preventing fluid migration between different zones of the wellbore, ensuring the integrity and safety of fracturing operations in extreme conditions.

Vertechs' innovation in HPHT frac plugs is rooted in advanced materials science and engineering excellence. These frac plugs are meticulously engineered from high-strength materials such as exotic alloys and advanced composites, ensuring durability and reliability in the harshest of conditions. Vertechs' engineering team leverages sophisticated design software and simulation tools to optimize the performance and functionality of HPHT frac plugs, delivering precise fit and effective zonal isolation in HPHT wells.

Vertechs' commitment to quality and excellence is reflected in its rigorous testing and validation procedures for HPHT frac plugs. Each frac plug undergoes extensive testing under simulated HPHT conditions to verify its performance and reliability. Vertechs' HPHT frac plugs are subjected to stringent validation protocols, including pressure testing, temperature cycling, and material analysis, ensuring they meet or exceed industry standards for HPHT applications.

Vertechs' HPHT frac plugs offer several advantages that contribute to enhanced operational efficiency in HPHT environments. By providing reliable zonal isolation, these frac plugs minimize the risk of fluid migration between different sections of the wellbore, enabling operators to conduct fracturing operations more efficiently and effectively. This results in reduced downtime, increased productivity, and improved overall operational efficiency for oil and gas operators.

Vertechs' HPHT frac plug technology prioritizes safety and reliability in HPHT fracturing operations. These frac plugs are engineered to withstand extreme pressures and temperatures, minimizing the risk of wellbore integrity issues such as fluid migration and gas migration. By ensuring reliable zonal isolation, Vertechs' HPHT frac plugs help mitigate the risk of accidents, blowouts, and environmental contamination, enhancing safety and environmental protection in HPHT environments.

Discover limitless possibilities with Vertechs Group. Your gateway to innovation and excellence. For inquiries, contact us at +86 28 8325 7686 or drop by Unit 2, Building 6, No.1166 Tianlong Avenue, Jinniu High-Tech Industrial Park, Chengdu, Sichuan, P.R. China. Reach out via email at admin@vertechs.com or marketing@vertechs.com. Explore a future of cutting-edge solutions with Vertechs – where technology meets vision. Visit our official website https://www.vertechs.com/ for more information. Elevate your business with Vertechs today.

Read Our One More Blog(1): 5 Key Advantages of Using Composite Frac Plug Material in Well Completions

Read Our One More Blog(2): From Concept to Execution: Mastering MPD Drilling Systems