Managed Pressure Drilling (MPD) represents a significant advancement in drilling technology, offering enhanced control and precision during drilling operations. Unlike traditional drilling methods, which rely solely on mud weight to control downhole pressure, MPD utilizes advanced equipment and techniques to actively manage wellbore pressure throughout the drilling process. This results in improved safety, increased efficiency, and reduced environmental impact.

As drilling operations move into increasingly challenging environments, the demand for advanced MPD solutions continues to grow. Operators require reliable MPD systems that can deliver precise pressure control, mitigate drilling hazards, and optimize wellbore integrity. Vertechs, a leading provider of oilfield technology solutions, is at the forefront of MPD drilling advancements, offering innovative solutions designed to meet the evolving needs of the industry.

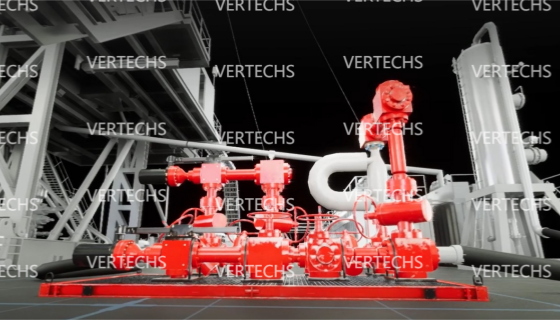

Vertechs offers a comprehensive range of MPD equipment engineered to deliver unparalleled performance and reliability. From advanced choke and manifold systems to cutting-edge pressure control devices, Vertechs' MPD solutions are designed to optimize drilling operations in a wide range of environments, including deepwater, high-pressure, and high-temperature wells.

Vertechs' MPD systems are complemented by sophisticated software solutions that provide real-time monitoring, analysis, and optimization of drilling parameters. These integrated software platforms enable operators to make informed decisions, anticipate drilling challenges, and adjust drilling parameters in response to changing downhole conditions, ensuring maximum drilling efficiency and safety.

Safety is paramount in MPD drilling operations, and Vertechs' solutions are equipped with a variety of advanced safety features to protect personnel, equipment, and the environment. From automated shut-in systems to advanced kick detection algorithms, Vertechs' MPD systems are designed to minimize the risk of well control incidents and ensure safe and reliable drilling operations.

By leveraging Vertechs' advanced MPD technology, operators can achieve greater drilling efficiency, reduced non-productive time, and optimized wellbore construction. Precise pressure control and real-time monitoring capabilities enable operators to drill faster, more accurately, and with fewer disruptions, resulting in significant cost savings and increased productivity.

Vertechs' MPD systems provide superior wellbore control, minimizing the risk of drilling-related issues such as lost circulation, differential sticking, and formation damage. By maintaining constant wellbore pressure and fluid circulation, Vertechs' solutions help preserve wellbore integrity, extend equipment life, and maximize reservoir productivity.

MPD drilling offers several environmental benefits, including reduced drilling fluid consumption, minimized waste generation, and decreased risk of environmental incidents. Vertechs' MPD solutions are designed to minimize environmental impact by optimizing drilling operations, reducing resource consumption, and mitigating the risk of drilling-related pollution.

Discover the forefront of energy technology with Vertechs Group. Our Chengdu headquarters at Unit 2, Building 6, No.1166 Tianlong Avenue awaits your visit. Dive into our breakthrough solutions at https://www.vertechs.com/, call us at +86 28 8325 7686, or reach out via email at admin@vertechs.com and marketing@vertechs.com for expertise that shapes the future of energy.

Read Our One More Blog(1): Enhancing Well Integrity: Innovations in Wellbore Strengthening Techniques

Read Our One More Blog(2): Safety First: Mitigating Risks in High-Pressure Environments with MPD