In the world of oil and gas drilling, efficiency, safety, and cost control are always at the forefront of innovation. One of the most significant advancements in this field is Managed Pressure Drilling (MPD), a technique that has transformed the way wells are drilled. Unlike conventional drilling, MPD provides precise control over wellbore pressures, reducing the risks of kicks, blowouts, and lost circulation. This allows operators to navigate complex formations while maintaining drilling efficiency, something that traditional methods often struggle with.

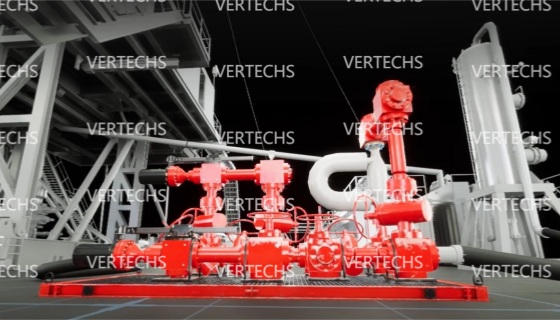

MPD works by dynamically adjusting wellbore pressures to maintain an optimal balance between formation pressure and hydrostatic pressure. Instead of relying solely on static mud weights, MPD systems use surface-controlled equipment such as choke manifolds and rotating control devices (RCDs) to fine-tune pressure conditions in real time. This is especially useful in formations with narrow pressure windows, where even slight deviations in pressure can lead to costly and dangerous well control issues.

One of the key advantages of MPD is its ability to reduce non-productive time (NPT). In traditional drilling, unexpected pressure fluctuations often result in costly delays as operators try to regain control. MPD mitigates this risk by allowing immediate adjustments to changing downhole conditions, keeping operations running smoothly. Additionally, it minimizes the amount of drilling fluid lost to the formation, reducing overall mud costs and waste disposal expenses.

Safety is another major benefit. Well control incidents, such as gas kicks, are a constant concern in the oil and gas industry. MPD helps prevent these issues by maintaining constant bottomhole pressure, ensuring that unwanted formation fluids do not enter the wellbore. This significantly reduces the risk of blowouts, making drilling operations safer for both personnel and the environment.

MPD is not a one-size-fits-all solution. There are different methods tailored to specific drilling challenges. Constant Bottomhole Pressure (CBHP) is one of the most commonly used techniques, where surface pressure is continuously adjusted to maintain a stable downhole environment. Another method, Pressurized Mud Cap Drilling (PMCD), is used in situations where severe lost circulation prevents returns to the surface. In this approach, drilling continues with a sacrificial fluid that maintains wellbore pressure without conventional circulation. Dual Gradient Drilling (DGD), often used in deepwater drilling, employs two different density fluids to better control pressure variations.

As the demand for more complex drilling projects increases, companies like Vertechs are at the forefront of MPD technology. With solutions such as IPC-MPD, iRCD, and IPC Titan - Smart Choke Retrofit, Vertechs is helping operators achieve safer, more efficient, and cost-effective drilling results. These technologies provide real-time monitoring and automated adjustments, allowing operators to maintain control in even the most challenging environments.

Looking ahead, the future of MPD is set to evolve even further. The integration of artificial intelligence and automation will make real-time adjustments even more precise, reducing the need for manual intervention. Additionally, the push for sustainability in drilling will likely see MPD being optimized to minimize environmental impact, reducing fluid loss and improving energy efficiency.

At Vertechs, we are committed to delivering top-tier energy technology solutions that drive innovation and efficiency in the industry. Our comprehensive range of services includes digital application upgrades, artificial intelligence engineering applications, and disruptive downhole technology products, all designed to meet the evolving needs of our clients. With a focus on customer value, we strive to provide cutting-edge technologies and solutions that not only enhance operational performance but also contribute to a sustainable future.

We invite you to explore how our expertise can benefit your operations. Reach out to us through our contact page, via email at engineering@vertechs.com, or connect with us on LinkedIn. Let's work together to achieve excellence in energy technology.

Read Our One More Blog(1): Benefits of Extended Range & HPHT Frac Plugs in Deepwater

Read Our One More Blog(2): Unleashing Potential: Exploring MPD Drilling Applications