In the oil and gas industry, wellbore strengthening is a crucial technique that reinforces well integrity, prevents lost circulation, and reduces drilling failures. This process enhances the mechanical strength of the wellbore, allowing it to withstand high-pressure conditions and minimize costly interruptions.

During drilling operations, the wellbore faces significant internal and external stresses. Without proper strengthening, issues such as lost circulation (where drilling fluids escape into the surrounding formation) can arise, leading to well instability, increased costs, and operational delays.

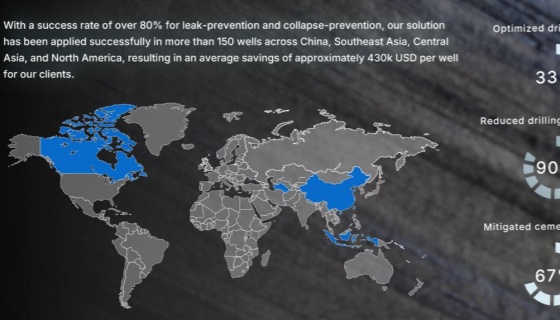

The Real-Time Wellbore Strengthening Solution (RWSS) by Vertechs Group is designed to reinforce weak formations and seal microfractures, preventing unwanted fluid migration and enhancing overall drilling efficiency.

1. Stress Redistribution & Fracture Sealing

One of the core principles of wellbore strengthening is stress redistribution. When drilling mud or specialized plugging materials enter fractures, they create a mechanical seal, preventing further fluid invasion. This process alters stress distribution around the wellbore, making it more resistant to pressure changes. RWSS incorporates advanced sealing agents and wellbore-compatible materials to enhance fracture resistance and maintain stability. These materials help prevent lost circulation by sealing microfractures effectively and reinforcing weak formations without compromising drilling performance.

2. Fracture Closure & Propagation Control

Uncontrolled fracture propagation can cause wellbore instability. To prevent this, high-performance bridging materials are used to plug fractures and stop their growth. By sealing these fractures, drilling operations can proceed smoothly without unexpected interruptions. RWSS ensures fracture closure by employing real-time monitoring and precisely engineered bridging particles, which provide immediate wellbore reinforcement in challenging formations and reliable control over fluid migration and fracture propagation.

3. Formation Enhancement with Engineered Fluids

Another effective approach is using engineered drilling fluids that contain sealing particles. These fluids reinforce the rock formation, enhancing its structural integrity and minimizing fluid loss. RWSS integrates with advanced drilling fluids to strengthen the wellbore while optimizing mud weight and viscosity. This results in reduced downtime due to fluid loss prevention and improved wellbore stability in narrow and high-pressure drilling environments.

To achieve the best results, operators should utilize RWSS from Vertechs Group to optimize real-time wellbore reinforcement, implement real-time monitoring to detect and address lost circulation early, and adjust mud weight and drilling parameters to maintain stability under varying conditions.

Drilling failures can be both costly and dangerous, making wellbore strengthening essential for maintaining smooth operations. By addressing key risks, it helps prevent major operational issues, ensuring better performance and safety. Here’s how wellbore strengthening mitigates common drilling challenges:

· Prevents Wellbore Collapse – Reinforcing the wellbore structure with strengthening materials helps prevent sudden collapses that could lead to costly well control incidents and operational downtime.

· Minimizes Lost Circulation – Solutions like wizard plugs effectively seal fractures, preventing drilling fluids from escaping into surrounding formations, thus reducing fluid loss and ensuring consistent pressure control.

· Enhances Drilling Efficiency – A strengthened wellbore allows for deeper, more stable drilling without interruptions, boosting overall productivity while minimizing risks and delays in the drilling process.

· Improves Well Integrity – Tools like slim hole frac plugs enhance the stability of narrow wellbores, ensuring long-term well integrity and minimizing the likelihood of future failures, contributing to more reliable operations over time.

Effective wellbore strengthening plays a vital role in maintaining operational efficiency. The RWSS solution from Vertechs Group provides cutting-edge materials and real-time monitoring capabilities, ensuring reliable well integrity and reduced operational risks. Want to optimize your wellbore strengthening strategy? Connect with Vertechs Group (engineering@vertechs.com) today to learn more about RWSS and how it can enhance your drilling performance.

Read Our One More Blog(1): Unleashing Potential: Exploring MPD Drilling Applications

Read Our One More Blog(2): Maximizing Pressure Handling in Frac Operations with Vertechs' 10,000 psi Rated Dissolvable Frac Plug