In the ever-evolving oil and gas industry, safety and efficiency are paramount. Managed Pressure Drilling (MPD) has emerged as a groundbreaking technology that addresses the challenges associated with drilling in high-pressure environments. By providing precise control over wellbore pressures, MPD enhances safety and mitigates risks, making it an indispensable tool for modern drilling operations. This article explores how MPD works, its benefits, and its role in ensuring safety in high-pressure environments.

One of the most significant safety benefits of MPD is its ability to prevent well control incidents. In conventional drilling, uncontrolled influxes of formation fluids (kicks) can lead to dangerous blowouts. Managed Pressure Drilling mitigates this risk by maintaining constant pressure control, allowing for immediate response to any pressure changes. This proactive approach significantly reduces the likelihood of kicks and blowouts, enhancing overall well safety.

Drilling in High-Pressure High-Temperature (HPHT) environments presents unique challenges due to the extreme conditions. Managed Pressure Drilling is particularly effective in these scenarios, as it allows for precise management of the high pressures encountered. By adjusting the pressure in real-time, MPD ensures that the wellbore remains stable, reducing the risk of catastrophic failures. This capability is critical for safely drilling HPHT wells, where conventional methods often fall short.

Safety incidents often lead to significant non-productive time (NPT), as operations must be halted to address the issues. Managed Pressure Drilling reduces NPT by preventing these incidents from occurring in the first place. The real-time monitoring and adjustment capabilities of MPD mean that potential problems are identified and mitigated before they can escalate. This proactive approach not only enhances safety but also improves overall drilling efficiency.

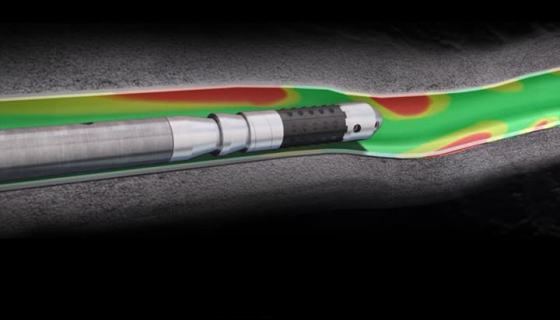

The ability to manage pressure in real-time is a cornerstone of MPD’s effectiveness. Pressure sensors and flow meters continuously monitor wellbore conditions, providing operators with the data needed to make immediate adjustments. This real-time management ensures that the pressure remains within safe limits, preventing the conditions that lead to well control incidents.

Maintaining wellbore stability is crucial in high-pressure environments. Managed Pressure Drilling enhances stability by constantly adjusting the pressure to counteract destabilizing forces. This continuous adjustment reduces the risk of wellbore collapse and other stability-related issues, ensuring a safer drilling process. Enhanced stability also means that operations can proceed more smoothly, with fewer interruptions.

Managed Pressure Drilling provides a robust framework for managing the risks associated with high-pressure drilling. By offering precise control over wellbore pressures, MPD reduces the likelihood of encountering dangerous conditions. This improved risk management framework is essential for safely drilling in challenging environments, where traditional methods may be inadequate.

Join Vertechs Group in leading the energy revolution. Visit our Chengdu office at Unit 2, Building 6, No.1166 Tianlong Avenue, or explore our solutions at https://www.vertechs.com/. Contact us at +86 28 8325 7686, or email admin@vertechs.com and marketing@vertechs.com for innovative approaches to your energy challenges.